Welcome to Maginito Limited.

Maginito Limited was established by Mkango Resources Ltd (TSXV/AIM:MKA) (www.mkango.ca), which holds a 79.4% interest in Maginito, to pursue downstream green technology opportunities in the rare earths supply chain, encompassing NdFeB magnet recycling and innovative rare earth alloy, magnet and separation technologies, underpinned by access to sustainably sourced primary and secondary rare earth raw materials. The company’s strategy for value creation is geared to accelerating growth in the electric vehicle market, wind power generation and other industries driven by decarbonisation of the economy.

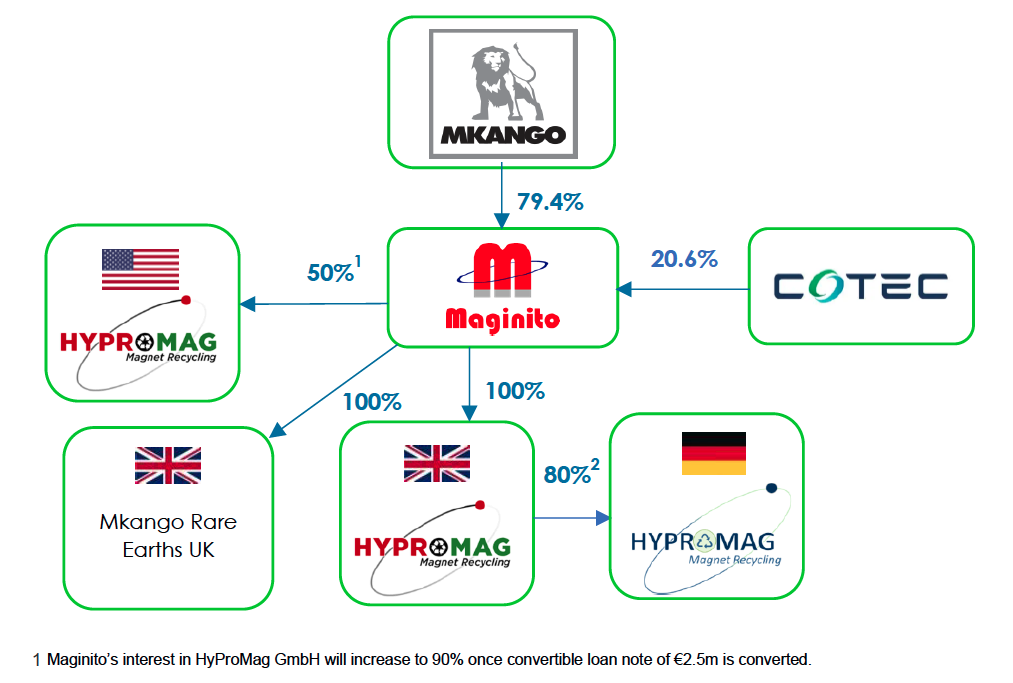

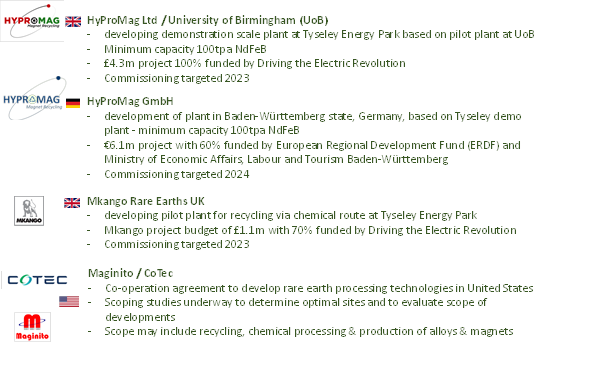

In March 2023, Mkango and CoTec announced that they had closed a £1.5 million investment by CoTec into Maginito for a 10% interest, with an option to increase to 20.6%. In October 2023, CoTec converted its £2 million convertible loan note in Mkango into additional shares of Mkango's subsidiary Maginito Ltd. As a result of the conversion, CoTec's equity position in Maginito increased from 10% to 20.6%. Maginito owns 100% of HyProMag Limited. Maginito and CoTec agreed to collaborate on the commercialisation of downstream rare earth technologies in the United States, and Mkango Rare Earths UK Ltd. was transferred to become a subsidiary of Maginito. Maginito and CoTec are evaluating development of recycling, chemical processing alloy, and magnet manufacturing in the United States, with scoping studies and site selection underway in advance of detailed feasibility studies, and ongoing discussions with potential customers and recycling partners.

Maginito now holds a 100% interest in HyProMag Limited (www.hypromag.com) focused on short loop rare earth magnet recycling in the UK, a 90% direct and indirect interest (assuming conversion of Maginito’s recently announced convertible loan) in HyProMag GmbH (www.hypromag.de), a company focused on short loop rare earth magnet recycling in Germany, and a 100% interest in Mkango UK, a company focused on development of innovative hydrometallurgical technologies and long loop rare earth magnet recycling in the UK via a chemical route. A new US subsidiary, to be jointly owned by Maginito and CoTec, will be formed to develop rare earth technology opportunities in the United States.

HyProMag Ltd

The core technology being commercialised by HyProMag Ltd is the highly energy efficient, patented Hydrogen Processing of Magnet Scrap (“HPMS”) technology to extract and demagnetise NdFeB alloy powders from magnets embedded in scrap and redundant equipment.

HPMS is a key enabler for recycling of rare earth magnets in electronics, electric vehicles, robotics, wind turbines and other applications, with major competitive advantages in the rare earth magnet recycling sector, underpinned by approximately US$100m of R&D expenditure at the University of Birmingham (“UoB”) and with associated project partners. This is coupled with the ability to manufacture rare earth alloys and magnets with significantly reduced carbon footprint.

HyProMag was founded in 2018 by the late Professor Emeritus Rex Harris, former Head of The Magnetic Materials Group (“MMG”) within the School of Metallurgy and Materials at the University of Birmingham, Professor Allan Walton, current Head of the MMG, and two Honorary Fellows, Dr John Speight and Mr David Kennedy, leading world experts in the field of rare earth magnetic materials, alloys and hydrogen technology, with significant industry experience.

The HPMS process was originally developed within the MMG and subsequently licenced to HyProMag.

The MMG has been active in the field of rare earth alloys and processing of permanent magnets using hydrogen for over 40 years. Originated by Professor Emeritus Rex Harris, the hydrogen decrepitation method, which is used to reduce NdFeB alloys to a powder, is now ubiquitously employed in worldwide magnet processing.

HyProMag is establishing short loop recycling facilities for NdFeB magnets at Tyseley Energy Park in Birmingham, UK and other locations using the patented HPMS process to provide a sustainable solution for the supply of NdFeB magnets and alloys for a wide range of markets including, for example, automotive and electronics. Short loop magnet recycling is expected to have a significant environmental benefit, requiring an estimated 88% less energy versus primary mining to separation to metal alloy to magnet production. The plant at Tyseley Energy Park is being developed together with the UoB, with a minimum capacity of 100tpa NdFeB (neodymium, iron, boron). This £4.3 million project is being funded by Driving the Electric Revolution, an Industrial Strategy Challenge Fund challenge delivered by UK Research and Innovation (“UKRI”). The focus of the project is to take the HPMS technology to a greater scale and efficiency with revolutionary new design of processing equipment and extensive automation of processing methods for inert atmosphere powder handling and pressing. HyProMag is the primary industrial user and operator of the plant. First production is targeted for late 2023, which follows successful piloting at the UoB in 2022 as featured on BBC Midlands News: https://youtu.be/9P-dsNCffWw.

HyProMag GmbH

In November 2021, HyProMag established an 80%-owned subsidiary in Germany, HyProMag GmbH, to roll out commercialisation of HPMS technology into Germany and Europe. HyProMag GmbH is 20% owned (10% following conversion of the HyProMag GmbH convertible loan) by Professor Carlo Burkhardt of Pforzheim University, co-ordinator of the €14m SusMagPro (www.susmagpro.eu) and €13m REEsilience (www.reesilience.eu) EU funded recycling projects, with approximately 40 partners across the European supply chain.

HyProMag GmbH is developing a similar sized plant to that at Tyseley Energy Park. Initial capacity is expected to be a minimum of 100tpa NdFeB, comprising recycled rare earth sintered magnets and alloys and will be the first in Germany using the patented HPMS process, with first production targeted for 2024. Maginito has entered into a convertible loan agreement (the “HyProMag GmbH Convertible Loan”) with HyProMag GmbH. Under the terms of the HyProMag GmbH Convertible Loan, Maginito has granted HyProMag GmbH a loan facility for €2.5 million available to be drawn down in accordance with an agreed investment plan and convertible into a 50% equity interest in HyProMag GmbH.

This investment by Maginito will contribute to the matched funding requirements to unlock the €3.7 million grants announced by Mkango on November 23, 2022, for development of the production facility in Baden-Württemberg State.

Mkango UK

Mkango UK is establishing a pilot plant at Tyseley Energy Park to chemically process recycled HPMS NdFeB powder and magnet swarf (i.e. the powder produced from grinding and finishing magnets) from a range of scrap sources including electronic waste, electric motors and wind turbines, complementing the short loop magnet recycling routes being developed in parallel by HyProMag. The £1.1 million pilot plant programme is being developed as part of the SCREAM Project (https://scream-uk.com/), for which 70% of the costs are being funded by UK Research and Innovation (UKRI) as part of the Driving the Electric Revolution challenge.

Near term production pipeline

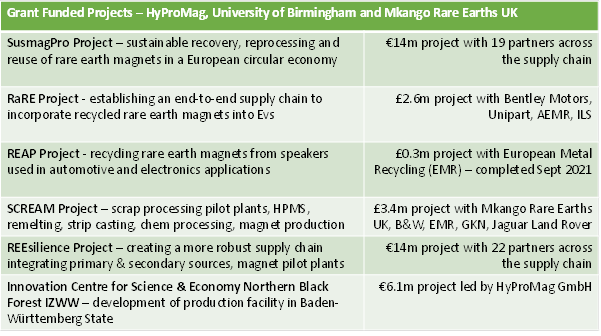

Technology development is supported by a number of Government grant funded projects in which Mkango Rare Earths UK, HyProMag Limited, HyProMag GmbH and University of Birmingham are participants:

Latest News

-

January 3, 2024Mkango Subsidiary Maginito And Cotec Form Hypromag USA Joint Venture And Commence Process To Appoint EPCM Provider For The Feasibility Study

-

October 11, 2023HyProMag’s Rare Earth Magnet Recycling Technology Selected As A Minerals Security Partnership Project

-

October 10, 2023Mkango And Cotec Provide Update On Roll-Out Of HyProMag’s Rare Earth Magnet Recycling Technology Into The United States